In the industrial field, the stability and efficiency of equipment directly affect the operation of the production line. Temperature control, as a key parameter for the operation of industrial equipment, determines whether the equipment can operate in an efficient and safe state. The NTC thermistors and temperature sensors produced by Nanjing Shiheng Electronic Technology Co., Ltd. play a vital role in many industrial equipment to ensure the temperature accuracy and safety of the equipment.

Products and application scenarios

-

NTC thermistor - accurate temperature detection

Application equipment: motor drive, inverter, industrial power supply, generator set

In industrial equipment, motor drives and inverters require accurate temperature monitoring to ensure their safe and stable operation. Motor drives and inverters are prone to heat up under high loads, and excessive temperatures may cause equipment performance degradation or even failure. Nanjing Shiheng Electronics' NTC thermistors provide real-time temperature data to the control system by detecting temperature changes inside the equipment to ensure that the equipment operates within a safe range.

How to install and work: NTC thermistors can be directly embedded in the cooling system of the motor coil or inverter. The temperature signal is fed back to the control system through the change in resistance value. The system automatically adjusts the cooling fan or other heat dissipation measures to ensure that the equipment maintains a suitable temperature while operating efficiently.

-

Temperature Sensor - Precision Temperature Monitoring

Application Equipment: Industrial Heating Equipment, Injection Molding Machine, Air Compressor

Temperature control is a key factor in production quality during the operation of industrial heating equipment and injection molding machines. Temperature sensors are used in these devices to ensure that the temperature of the heating element or injection molding head is kept within a precise range to ensure the stability and consistency of the production process. For air compressors, temperature sensors are used to monitor the temperature of the machine body and the surrounding environment to prevent equipment failure at high temperatures.

How to Install and Work: Temperature sensors are usually installed in key parts of heating equipment, injection molding machines or air compressors, such as heating elements, cooling systems or cylinder exteriors, and transmit signals to the control system by measuring the temperature of the equipment in real time. The control system automatically adjusts the temperature output or cooling measures based on the feedback data to ensure that the equipment operates at a stable temperature.

-

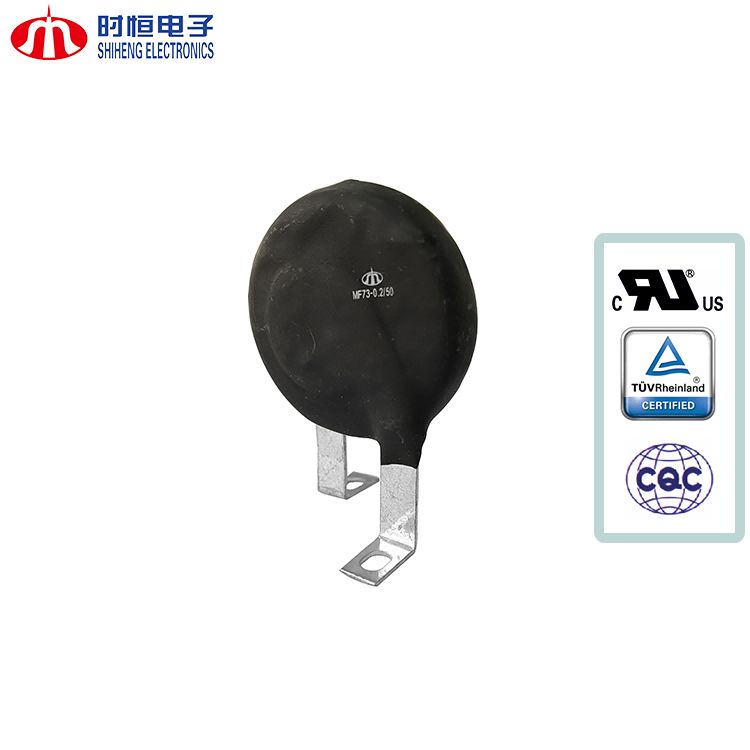

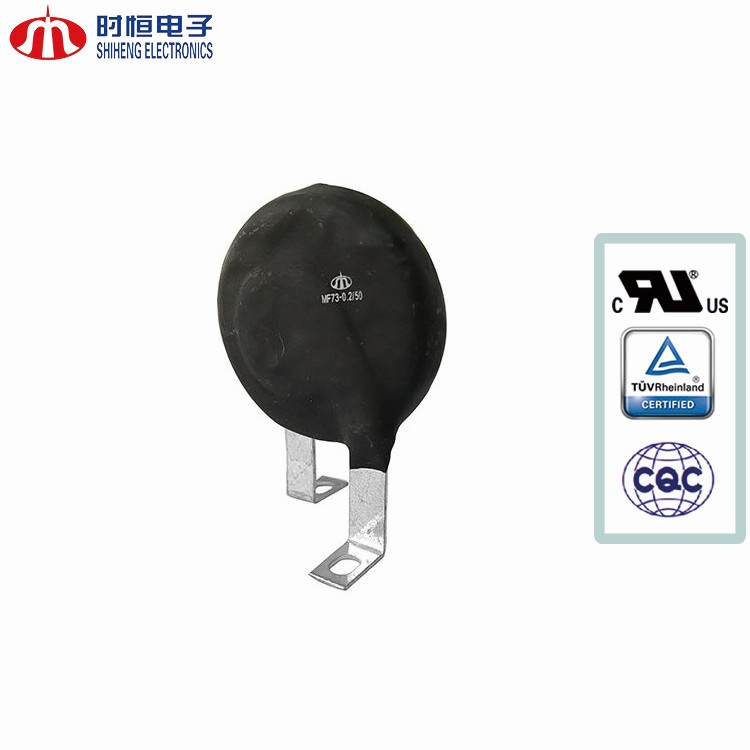

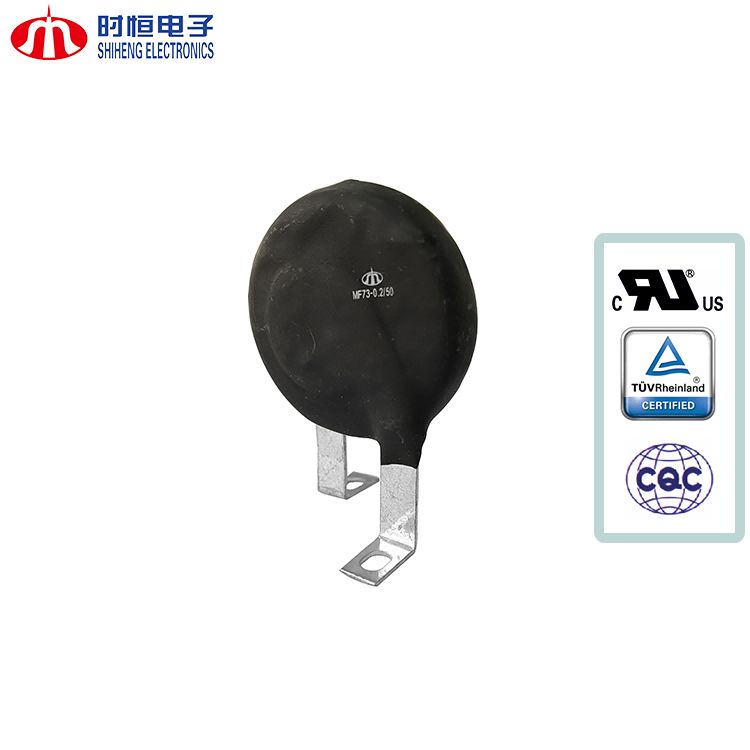

Power Thermistor - Current Protection and Temperature Management

Application Equipment: Welding Equipment, Power Transformer, Industrial UPS

Power thermistors play a vital role in current protection and temperature management in high-power equipment such as welding equipment, power transformers and industrial UPS. When this type of equipment starts, the current impact is large. The power thermistor automatically adjusts the resistance value to effectively limit the current and prevent the equipment from overheating during startup and high-load operation. At the same time, in the power transformer, the power thermistor can be used to continuously monitor the internal temperature of the equipment to ensure that the equipment does not overheat and avoid system failures caused by excessive temperature.

How to install and work: Power thermistors are usually installed at the power input end of welding equipment or in the circuit board of industrial UPS, directly involved in current protection and temperature management. At startup, when the internal temperature of the equipment is too high or the current is too large, the resistance of the thermistor increases, limiting the flow of current, thereby protecting the equipment and avoiding high-temperature failures.

Product working principle and installation method

The NTC thermistors and temperature sensors produced by Nanjing Shiheng Electronic Technology Co., Ltd. can sense temperature changes in industrial equipment in real time and feedback to the control system through their unique resistance change principle. When the temperature rises, the resistance of the NTC thermistor decreases, and the system dynamically adjusts the working state of the equipment based on this change to avoid equipment damage or performance degradation caused by excessive temperature. The power thermistor adjusts its own resistance according to the current change to achieve current protection and temperature control of the equipment.

In terms of installation, NTC thermistors and temperature sensors are usually embedded or fixed in key temperature control locations inside the equipment, such as around motor coils, cooling systems or heating elements, to ensure that temperature changes can be detected quickly. Power thermistors are generally installed at the power input or main circuit to cope with the current shock of the equipment and provide long-term protection.

Key role in equipment

1. Ensure stable operation of equipment: Through real-time temperature monitoring, Nanjing Shiheng Electronics' thermistors and temperature sensors ensure that industrial equipment operates within a safe temperature range to avoid equipment failures caused by excessive temperatures.

2. Improve production efficiency and product quality: In injection molding machines and heating equipment, precise temperature control directly affects the quality and consistency of the production process. Nanjing Shiheng Electronics' products help customers improve the stability of production lines and improve product production quality.

3. Extend equipment life: Power thermistors effectively prevent equipment damage caused by overcurrent and overheating, extend the service life of equipment, reduce the frequency of repairs and downtime, and save maintenance costs for customers.

Nanjing Shiheng Electronic Technology Co., Ltd.'s NTC thermistors and temperature sensors provide reliable temperature detection and current protection solutions in industrial equipment, and are widely used in motor drives, industrial heating equipment, welding equipment and other industrial equipment. We are committed to providing customers with efficient and accurate temperature management solutions to ensure the safety and reliability of equipment, help customers improve production efficiency and reduce equipment failure rates.

Nanjing Shiheng Electronic Technology Co., Ltd. is a high-tech enterprise focusing on the production of power thermistors, temperature measuring thermistors and temperature sensors. The company's products are widely used in industrial equipment, medical equipment, new energy, home appliances and other fields. Through technological innovation, we are committed to providing high-precision and high-stability temperature measurement and control solutions to global customers.