Glass-Encapsulated vs Epoxy-Coated Thermistors: Which Should You Use?

May 16, 2025Introduction when designing a product that relies on temperature sensing, selecting the right thermistor package is just as critical as choosing the correct electrical specifications. Two of the most common types are glass-encapsulated thermistors and epoxy-coated thermistors. But how do you choose between them? The answer lies in understanding your application environment and reliability requirements.

|

|

In this article, we compare glass and epoxy packages head-to-head to help you select the best fit for your design.

1. Construction & material differences:

2. Thermal and environmental performance

|

Feature |

Epoxy-Coated |

Glass-Encapsulated |

|

Max Operating Temp |

~125°C |

Up to 250°C |

|

Moisture Resistance |

Moderate |

Excellent |

|

Chemical Resistance |

Limited |

Excellent |

|

Thermal Cycling Durability |

Good (typical use) |

Excellent (harsh environments) |

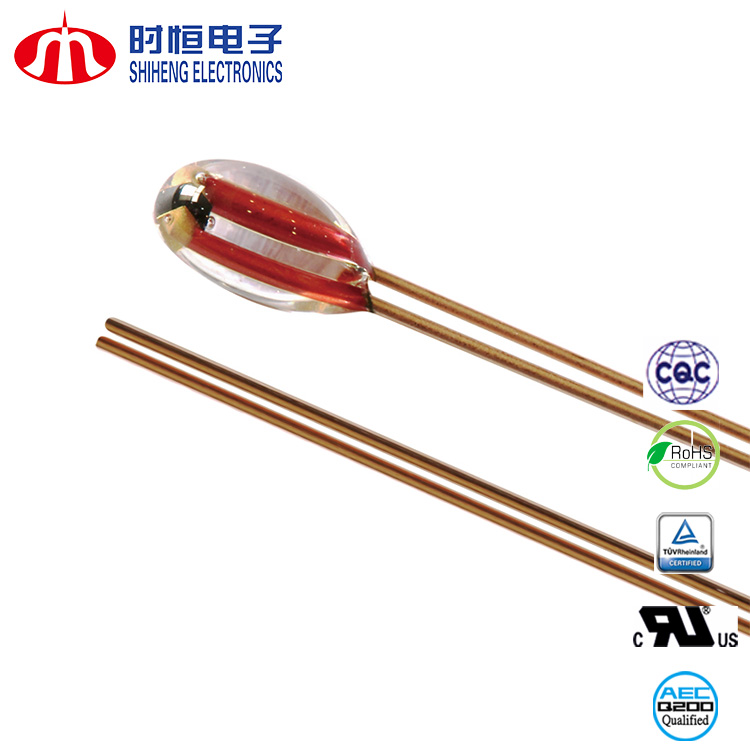

Glass-encapsulated thermistors, like our MF58 series, are ideal for applications exposed to repeated thermal cycling, high humidity, or chemical vapors.

3. Cost and application trade-offs

If your design requires long-term reliability under harsh conditions, glass is often worth the additional investment.

4. Mechanical considerations glass thermistors are more rigid and may require careful handling during installation. Epoxy-coated versions, in contrast, offer more mechanical flexibility, making them easier to mount or pot into assemblies.

Which should you choose? Ask yourself:

|

|

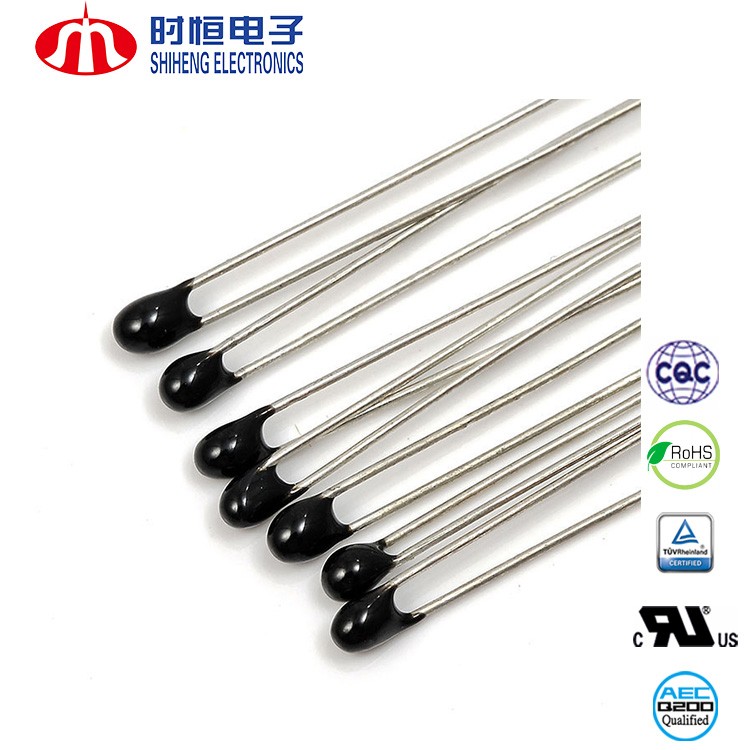

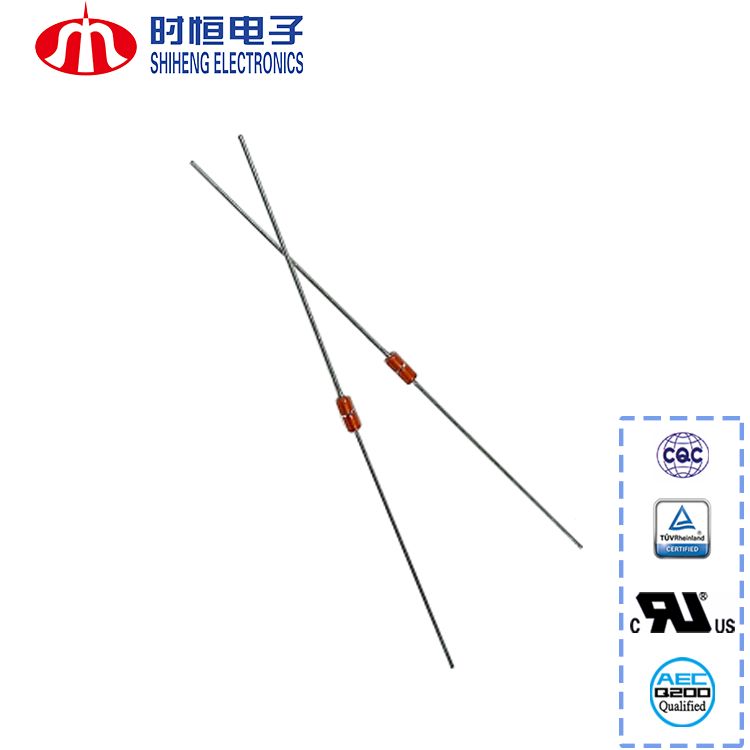

If you need a durable, high-precision sensor for challenging environments, glass-encapsulated thermistors like our MF58 series are the superior choice. For cost-sensitive, moderate-duty applications, epoxy-coated thermistors such as our MF52 series are often more than sufficient.

Conclusion choosing the right thermistor package depends on balancing performance, cost, and application environment. At Nanjing Shiheng Electronic Technology Co., Ltd., we offer both epoxy and glass thermistors with rapid customization options and global certifications.

Still unsure which to choose? Contact us for expert guidance, samples, or customized solutions tailored to your project.