Enhancing Automotive Transmission Systems with NTC Thermistors: A Technical Perspective

Feb 17, 2025In the world of automotive engineering, precision and reliability are nonnegotiable. When it comes to designing and maintaining automotive transmissions, one of the most critical challenges is managing heat. Excessive temperatures can lead to component wear, reduced efficiency, and even system failure. This is where NTC thermistors come into play. As a leading provider of high-performance electronic components, Nanjing Shiheng is here to explore how NTC thermistors are revolutionizing temperature monitoring in automotive transmissions, ensuring optimal performance and longevity.

The Importance of Temperature Management in Automotive Transmissions

Automotive transmissions are the backbone of any vehicle, responsible for transferring power from the engine to the wheels. However, they operate under extreme conditions, including:

Without proper temperature management, these factors can lead to:

To address these challenges, real-time temperature monitoring is essential – and NTC thermistors are the ideal solution.

How NTC Thermistors Enhance Transmission Performance

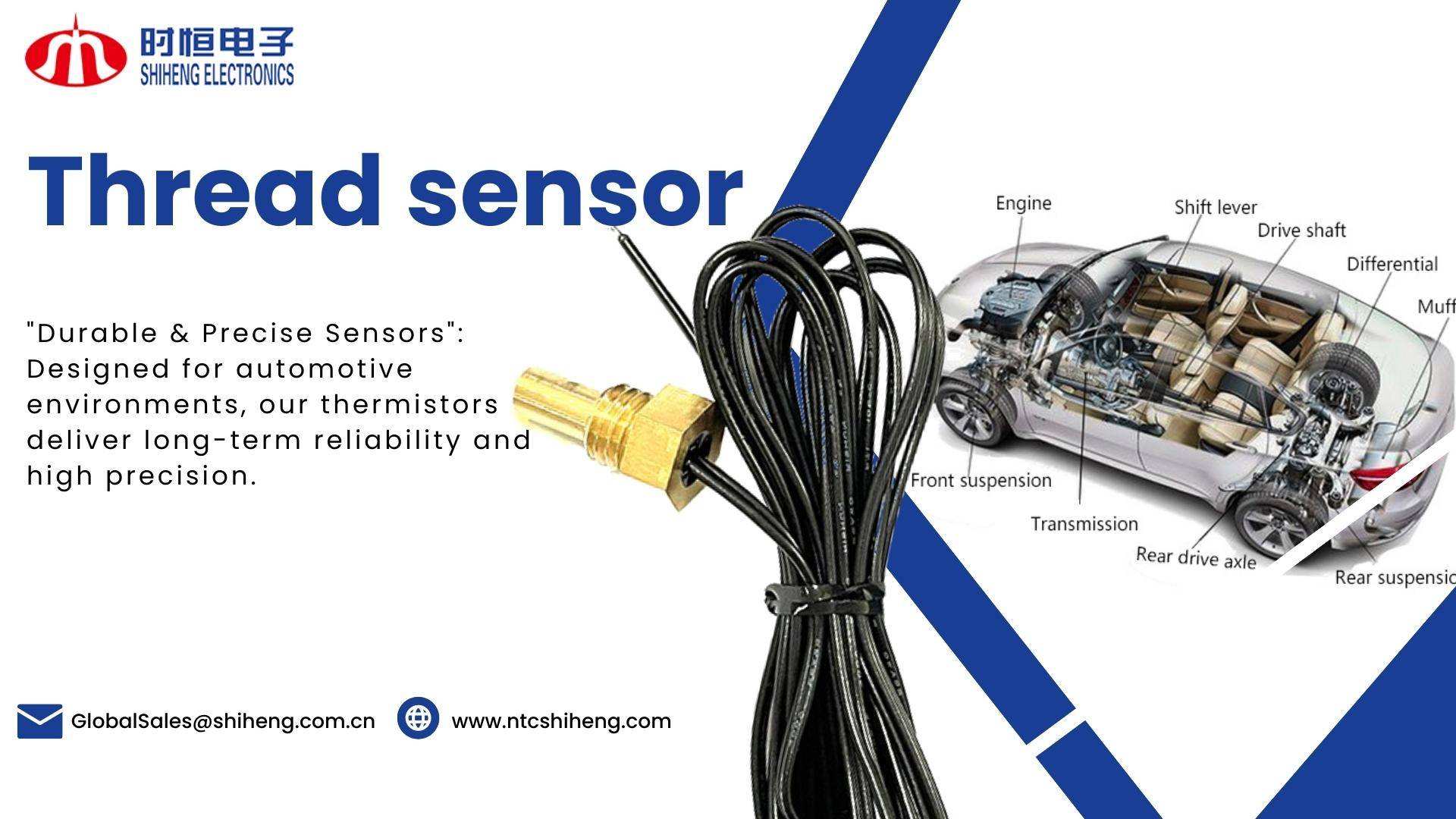

NTC (Negative Temperature Coefficient) thermistors are highly sensitive temperature sensors that decrease in resistance as temperature increases. In automotive transmissions, they are strategically integrated into critical areas to provide accurate and reliable temperature data. Here’s how they work:

1. Temperature Sensing: The thermistor detects temperature changes in transmission fluid, gearboxes, or clutch systems.

2. Signal Transmission: The resistance change is converted into an electrical signal and sent to the vehicle’s Engine Control Unit (ECU) or Transmission Control Unit (TCU).

3. System Optimization: Based on the temperature data, the ECU or TCU can:

Applications of NTC Thermistors in Automotive Transmissions

Transmission Fluid Monitoring: Ensuring optimal fluid temperature for lubrication and cooling.

Gearbox Temperature Control: Preventing overheating during highstress operations.

Clutch System Protection: Monitoring clutch plate temperatures to reduce wear and extend lifespan.

Hybrid and Electric Vehicle Transmissions: Managing temperatures in advanced EV and hybrid systems, where thermal management is critical for battery and motor performance.

At Nanjing Shiheng, we understand the unique challenges faced by automotive transmissions. Our NTC thermistors, such as the MF52 Series, are engineered to meet the highest industry standards, offering:

For automotive transmissions, integrating NTC thermistors is not just a choice – it’s a necessity. These components provide the precision, reliability, and durability needed to ensure optimal performance and longevity in today’s demanding automotive environments.

At Nanjing Shiheng, we are committed to delivering cutting-edge solutions that meet the evolving needs of the automotive industry. Whether you’re designing next generation transmissions or optimizing existing systems, our NTC thermistors are here to help you stay ahead of the curve.

Explore our NTC thermistor solutionsand discover how we can support your automotive projects.